- Decision framework

Resilinc UFLPA Agent

The government supply chain is facing new compliance and procurement pressures as the Forced Labor Due Diligence Reporting Template (DDRT), U.S. Customs and Border Protection (CBP) enforcement changes, and evolving UFLPA compliance requirements converge. Since June 2022, CBP has examined more than 16,000 shipments, while the UFLPA Entity List has expanded by 78 new additions in 2025.

Chapter 1 | Introduction

In today’s manufacturing world, a single disruption can send shockwaves through the entire manufacturing supply chain.

With thousands of interconnected suppliers and just-in-time inventory models, even a minor event can lead to major losses. Factory fires, labor strikes, geopolitical conflicts, regulatory shifts, and natural disasters are no longer one-off events. They’re constant. They’re global. And they’re growing in complexity.

Despite this reality, most manufacturers still operate in a reactive mode. When disruptions hit, teams scramble to assess damage, identify alternate suppliers, and coordinate across siloed systems—often too late. This reactionary approach leads to delayed decisions, production halts, inflated costs, and lost revenue.

Enter agentic AI—your always-on, always-alert partner for your supply chain. Instead of waiting for the worst to happen, agentic AI supply chain monitoring does it for you. It tracks global events in real time, filters out the noise, and flags only what matters to your business. More importantly, it recommends what to do next—and can even kickstart mitigation workflows for you.

With research showing that up to 70% of disruptions are preventable, this is the moment to shift from reacting to predicting, from scrambling to strategizing. Agentic AI makes that shift possible.

Chapter 2 | What is agentic AI? And why now?

Agentic AI is a new kind of artificial intelligence—built to think for itself, learn as it goes, and handle complex tasks without needing constant human input.

These agents go far beyond predictive analytics or alerts—they operate with purpose, constantly evaluating supply chain dynamics and taking informed action.

Why now? Because supply chains are hitting a breaking point.

Supply chain complexity has exploded. In the first half of 2025 alone, general manufacturing saw a 15% spike in disruptions overall compared to the first half of 2024. Cyberattacks jumped 88%. Regulatory changes soared by 86%. And geopolitical disruptions? All-time high at 53%. Layer in factory disruptions, port closures, and extreme weather, and it’s clear: spreadsheets and manual workflows just can’t keep up.

Agentic AI provides a force multiplier. It connects the dots across siloed data, identifies sub-tier risks before they materialize, and executes mitigation workflows autonomously. It allows manufacturers to anticipate disruptions, reduce time-to-response, and maintain operational continuity.

Whether it’s a supplier acquisition in Latin America, tariff increases in Asia, or a labor walkout in the Midwest, Agentic AI ensures manufacturers are not just informed but prepared.

Chapter 3 | Closing the visibility gap across every tier

- Which parts are made at which specific supplier sites

- How events impact operational and financial performance

- Supplier compliance status and risk readiness

- Where operational bottlenecks or sustainability risks may emerge

Chapter 4 | Key capabilities for manufacturing supply chains

Resilinc’s agentic AI supply chain monitoring was built specifically to help manufacturers stay resilient in a world of constant supply chain disruption.

Here’s how it changes the game:

- See beyond Tier 1 with autonomous multi-tier mapping

Get clear, real-time visibility into your full supply network—down to the part-site level. Know which suppliers makes which components, and how sub-tier suppliers are connected to your top-line revenue. Identify single-sourced parts and potential line-down risks before they happen. - Catch disruptions as they happen

Monitor over 150 million global sources across 100+ languages to detect factory fires, labor protests, leadership changes, tariff shifts, and more—within minutes. - Know the impact in minutes

No more manual triage. Agentic AI instantly evaluates which SKUs, suppliers, and facilities are affected, how it could impact revenue or delivery timelines, and what to do about it. - Get smarter response plans, fast

Get tailored playbooks with supplier-validated sourcing alternatives, risk scores, and action items. One-click WarRooms let you collaborate with suppliers instantly. - Stay ahead on compliance

From Uyghur Forced Labor Prevention Act (UFLPA) to EU Deforestation Regulation (EUDR) to regional labor laws, agentic AI keeps tabs on the regulations that matter to your business. It automates assessments, collects documentation, flags risks, and can even initiate supplier outreach for you.

Chapter 5 | Inside real manufacturing disruptions

When disruption hits, speed matters

Manufacturing supply chains are under constant pressure- it’s not a matter of if disruptions will happen, but when. What separates resilient manufacturers from the rest is how quickly and effectively they respond.

That’s where agentic AI makes all the difference. Instead of reacting late, manufacturers using agentic AI respond in real time, with clear insight and decisive action.

How leading manufacturers use agentic AI

- Tariff hike on Asia-sourced components

Resilinc’s Tariffs Agent flags a sudden spike in duties. Within minutes, the agent traces affected SKUs and suggests alternate suppliers in low-tariff regions—helping sourcing teams to pivot quickly and avoid cost impacts before the new rates take effect. - Factory fire at U.S. injection molding site

A fire is reported at a facility producing engine cooling system components. Agentic AI sends a verified alert, evaluates which OEM programs are impacted, and models potential production delays. A mitigation workflow is activated, including backup suppliers and inventory buffers.

Labor disruptions increase

Labor disruptions have intensified across industries, driven by workforce shortages, union actions, and shifting economic conditions, leading to widespread operational setbacks and financial strain.

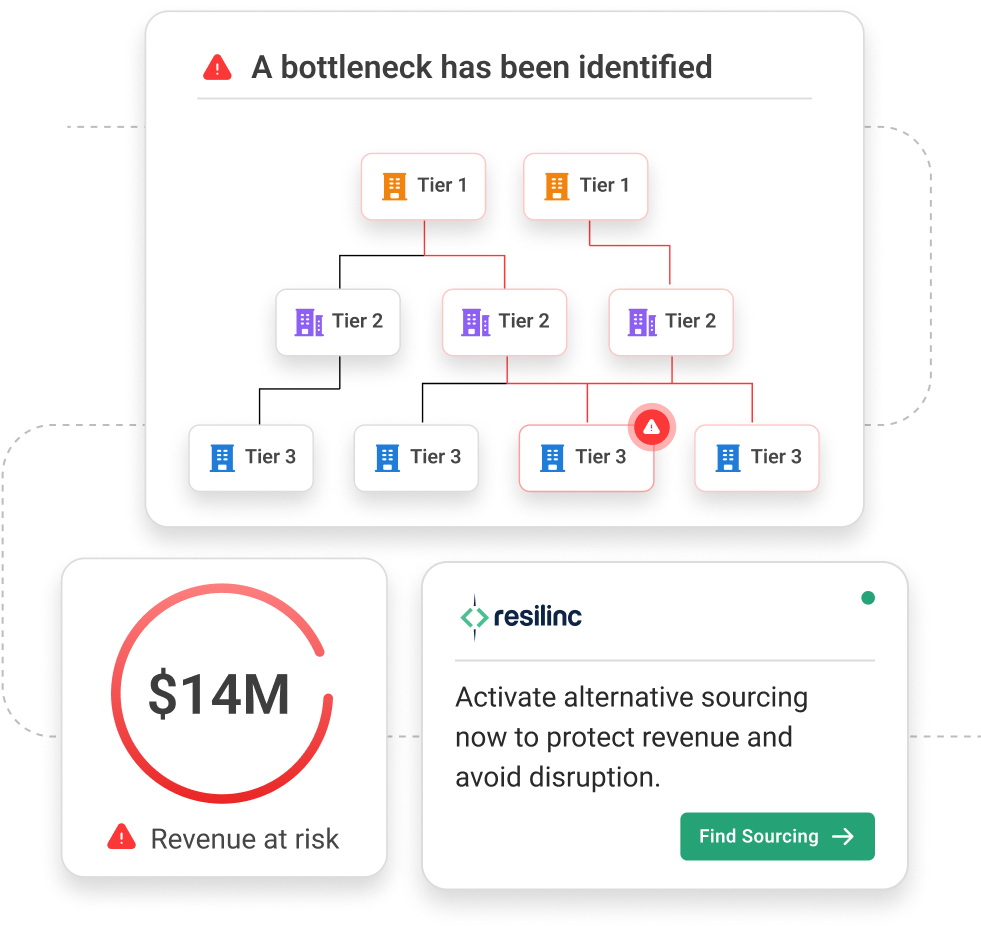

Image at Right

The government supply chain is facing new compliance and procurement pressures as the Forced Labor Due Diligence Reporting Template (DDRT), U.S. Customs and Border Protection (CBP) enforcement changes, and evolving UFLPA compliance requirements converge. Since June 2022, CBP has examined more than 16,000 shipments, while the UFLPA Entity List has expanded by 78 new additions in 2025.

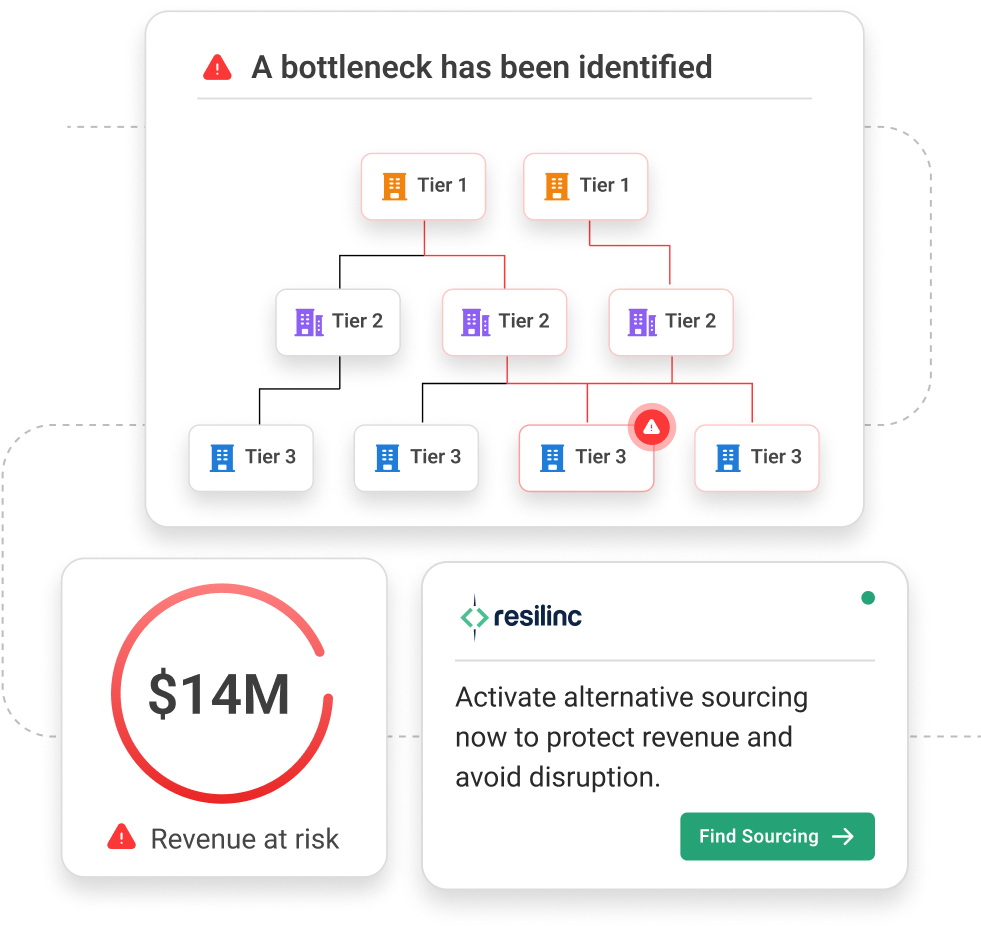

Image at Left

The government supply chain is facing new compliance and procurement pressures as the Forced Labor Due Diligence Reporting Template (DDRT), U.S. Customs and Border Protection (CBP) enforcement changes, and evolving UFLPA compliance requirements converge. Since June 2022, CBP has examined more than 16,000 shipments, while the UFLPA Entity List has expanded by 78 new additions in 2025.